Glenis Rose, JIS Writer

Workers at the liquid-egg plant located in the Montego Bay Freeport area prepare eggs for washing before they are processed. - Contributed photos

MONTEGO BAY, St. James:

The age-old debatable question, 'which came first, the chicken or the egg?', is an ongoing pastime that's good mental exercise for avid 'debaters', often ending with no clear winner.

But let's just focus on the eggs. There is no debate about when gone are the days of breaking eggs over hot steaming frying pans and the stocking up of egg shells in the busy kitchen areas of several hotels, thanks to the pasteurised liquid-egg product which has now become a fixture in hotels across western Jamaica.

When requests are made, all the chef has to do is to reach for a bottle of the product, which is always at arm's length, and pour in the frying pan; and as we say here in Jamaica, 'as yuh quint' breakfast is complete and the guests gleefully sit down to enjoy their morning meal.

Several chefs in the hotel sector across western Jamaica have found that preparations for breakfast have been made easier, less cumbersome and allow for shorter waiting periods by guests for their favourite omelette and other egg-ingredient breakfast.

Speaking with the Jamaica Information Service's executive sous chef at the Sunset Beach Hotel in Montego Bay, Washburn Lawrence, he said that the liquid-egg product has been found to be very convenient and easy to use.

Good for the hotel industry

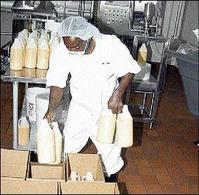

Mark Francis, a worker at the liquid-egg plant located in the Montego Bay Freeport area, is busy packaging the finished liquid-egg product.

"In our kitchen, we don't break eggs anymore and we don't import liquid egg anymore. We receive adequate supply from CPJ (Caribbean Producers Jamaica Limited) and all we have to do is to maintain the temperature. This product is very good for the hotel industry as we have at least 150 products that are used with the liquid egg on a daily basis. The demand for the product is vast and we use approximately 40 to 50 quarts per week."

André Bullock, junior sous chef at Sunset Beach Hotel, certainly agrees with how much easier his daily tasks are with this product. "I prefer to use the liquid egg because all you have to do is to pour from the bottle and watch the date, making sure that you are using it before it expires."

Pasteurised liquid egg is produced by CPJ at a liquid-egg plant located in the Montego Bay Freeport. The plant, considered as the first of its kind in the region, was established at a cost of $40 million and was commissioned into service in February 2007.

With preliminary plans already activated for expansion of the facilities and the possible exportation of the product to hotels in the wider Caribbean region and beyond, the establishment is expected to significantly enhance the consumption of eggs locally.

Sales manager at the CPJ in Montego Bay, Hugh Logan, said that the pasteurised liquid egg is in great demand in Jamaica among the hotels and has been found to be equal to all international standards.

Good response

"We have been in production now (since February 2007) and have had extremely good response. The advantage of liquid eggs is primarily an issue of food safety and quality of service. There is also a hidden cost-saving factor as the product affords 100 per cent yield, in that nothing or very little goes to waste in comparison to the cracking of eggs. The scope for liquid eggs holds very well because it offers much reduction in labour, time and preparation. Within the existing market, the opportunities are significant and more so with the anticipated opening of larger hotel properties which would be feeding large numbers of people at one time. Liquid eggs is on the rise and will continue to increase in Jamaica and the Caribbean", Mr. Logan added.

Addressing the plans for expansion in production, Mr. Logan said, "Our facility has been built with expansion in mind but also with the demands; certainly with the immediate and the next five to 10 years' demands, which would be met within the existing structure. It may mean adding components such as additional mixing tanks, but the facility itself has the ability to expand to meet whatever production demands there may be."

According to Mr. Logan, plans were afoot to have the product available in the local retail trade in the near future.

"In the long term, we will be looking at doing some consumer packaging but presently, we only do food-service distribution packaging; that's six bottles to one case, which would not suit small consumers or householders, but certainly in the near future, we would be heading down that road."

Pasteurised liquid egg is 100 per cent egg with no additives. Eggs are purchased and washed at about 95 degrees Fahrenheit to get rid of all bacteria. These are then sorted for impurities and afterwards, broken by an automatic machine, whereby the shells are separated from the liquid which then passes to a large storage mixing tank.

At this point, the liquid eggs are blended properly and move to a balance tank, then through the heat exchanger and pasteurising tubes where it is pasteurised at temperatures between 60 and 65 degrees Celsius where all bacteria are eliminated. The product is then passed back into the heat exchange for a rapid cooling from 60 degrees to between zero and five degrees Celsius.

Joint venture

The finished product is then bottled by way of a semi-automatic process and boxed for storage and/or delivery to hotels, mainly in western Jamaica.

Chief executive officer of CPJ Limited, Mark Hart, said, "We felt that it was important to produce liquid egg here in Jamaica and not having to import the product. We really want to support the local egg farmers and that's one of the main reasons why we established it. The project is a joint venture between the Jamaica Egg Farmers Association and Premium Producers. We have observed a 100 per cent acceptance by all those hotels that have started to use the locally produced liquid egg. We want to get all the other hotels to come on-board and support the project and more importantly, support the local farmers."

The liquid-egg factory receives a consistent supply of eggs through the Jamaica Egg Farmers Association which has a network of egg farmers located in many parishes, chiefly across eastern and central Jamaica.

And so, we are back to that debatable issue at the start of this feature, which comes first, the chicken or the egg? I am sure most will readily agree that in its various forms, they are both very delicious!

This is a special Gleaner feature in partnership with the Jamaica Information Service.